OUR WORKSHOP

Based in the heart of Hatton Garden, our workshop is a hub of creativity, tradition, and cutting-edge technology, dedicated to crafting the highest quality jewelry. By having an in-house workshop, we’re able to oversee every stage of the manufacturing process, from design and prototyping to the final polish, ensuring that each piece meets our exacting standards for excellence and detail.

THE PROCESS BEHIND THE SCENES

-

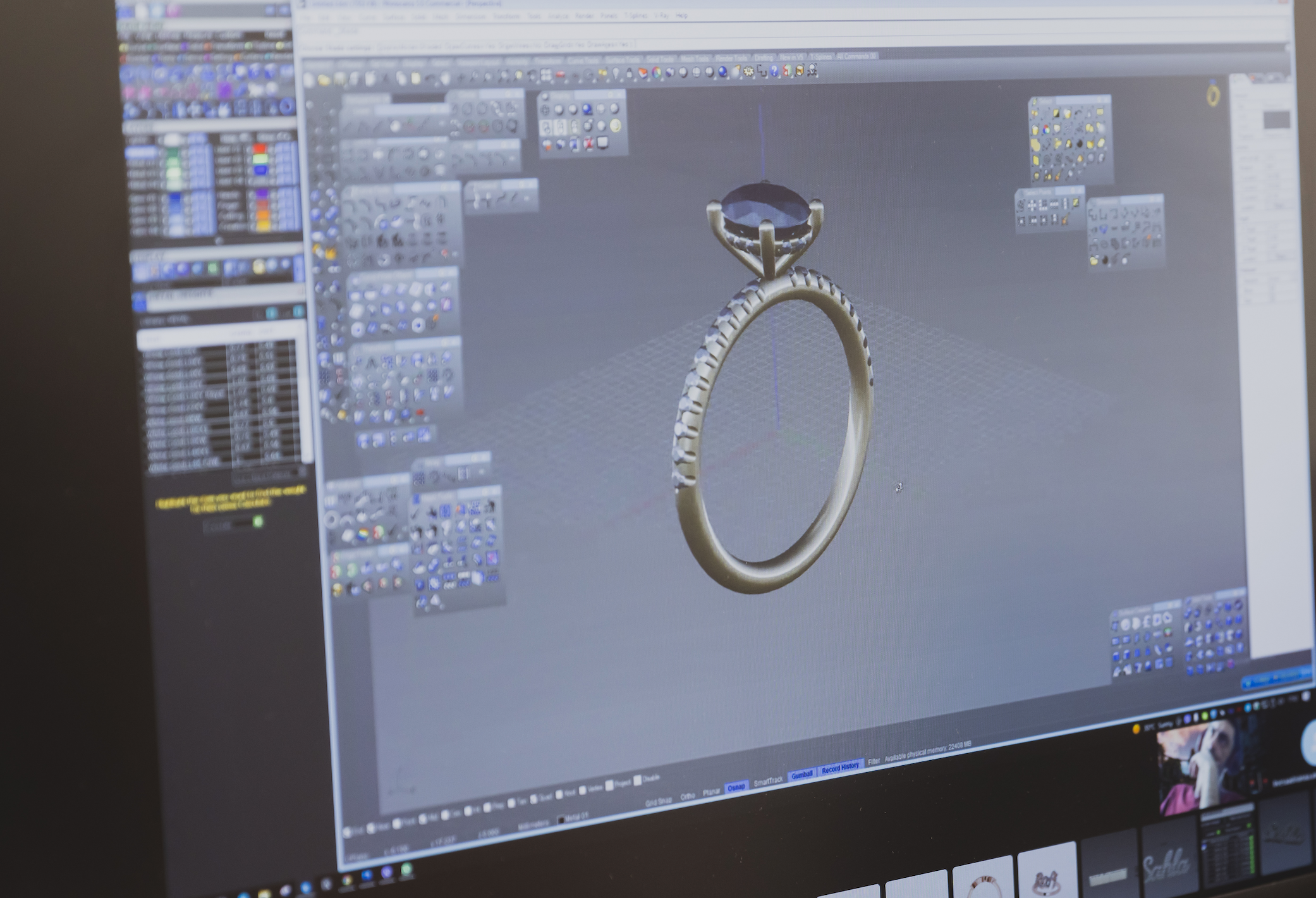

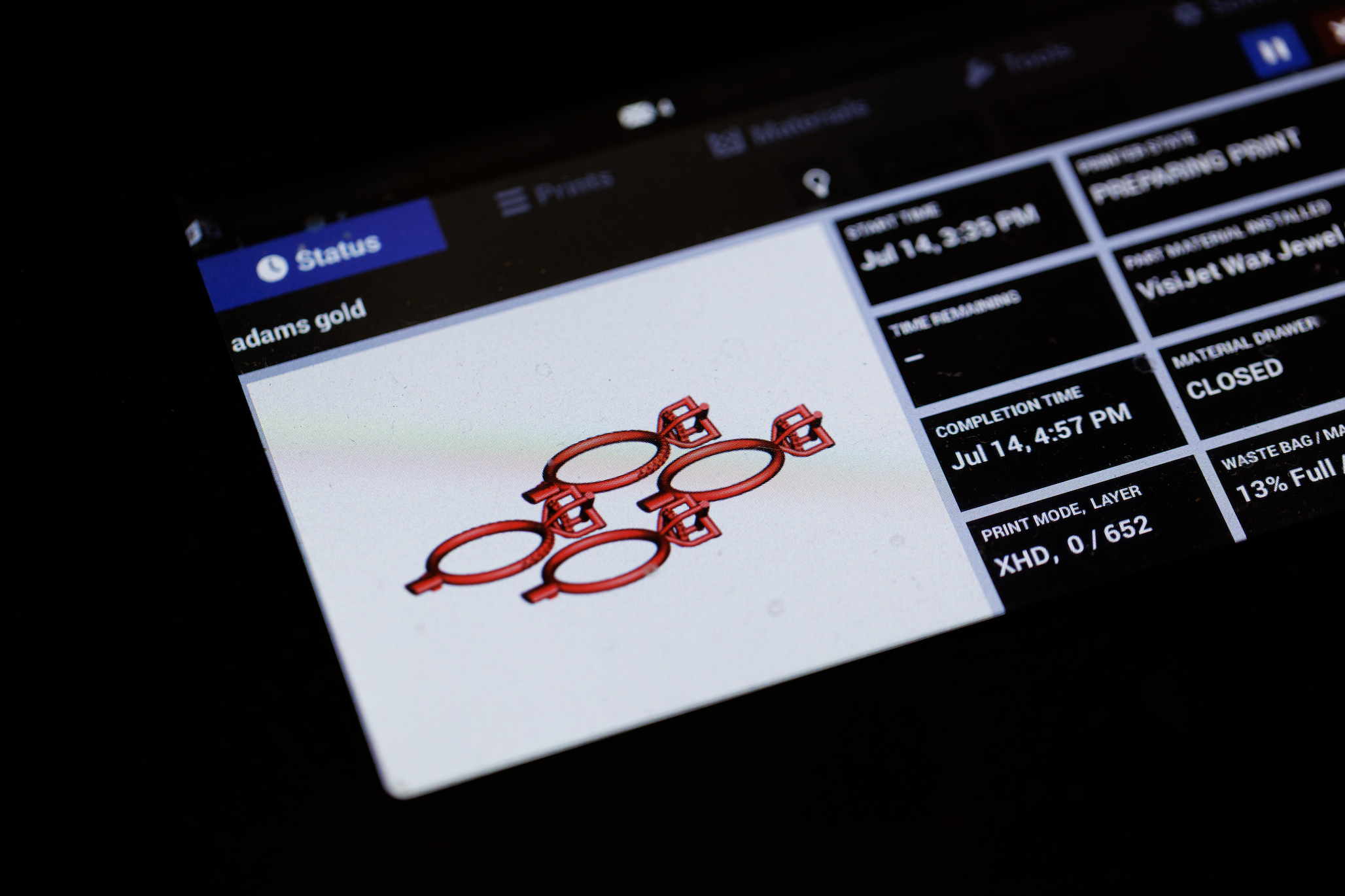

1. CAD

We begin by constructing a cad drawing of your agreed design. Once the CAD drawing is confirmed the piece is 3D printed into wax in preperation for casting.

-

2. CAST

The piece is then casted into a metal and colour of your choosing. Our casters use the most recent technology and materials to ensure the best quality that will last a lifetime.

-

3. ASSEMBLE & CLEAN

Our mounters then begin to assemble and clean your piece in order to get it prepped for setting.

-

4. SETTING

At the beginning of the process we would have worked closely with you to select a unique variety of gemstones, chosen with care from trusted diamond and gemstone suppliers. Each stone is then meticulously set and securely positioned to ensure durability of your custom piece.

-

5. POLISH

The piece is then expertly polished to reveal its radiant sparkle, transforming it into a timeless treasure.

-

6. DELIVERY

Once the piece is complete, it undergoes a final, meticulous quality check. These pieces are designed to last for generations, making them timeless additions to your life. After this final polish, your custom jewelry is carefully packaged and delivered, ready to become a part of your story and perhaps even a family heirloom for years to come.